-

Oilfield Equipment > Products & Services

Drill Through Equipment

Hydro's Drill Through equipment is designed

to provide reliable, safe, and effective operations.

DRILL THROUGH EQUIPMENT

Product Catalogue

Drilling & Spacer Spool

Hydro manufactures all sizes, pressure ratings, temperature ratings, and lengths of drilling spool with top and bottom flanges.

Adapters

A pressure-containing piece of equipment, with connections of different sizes and pressure ratings.

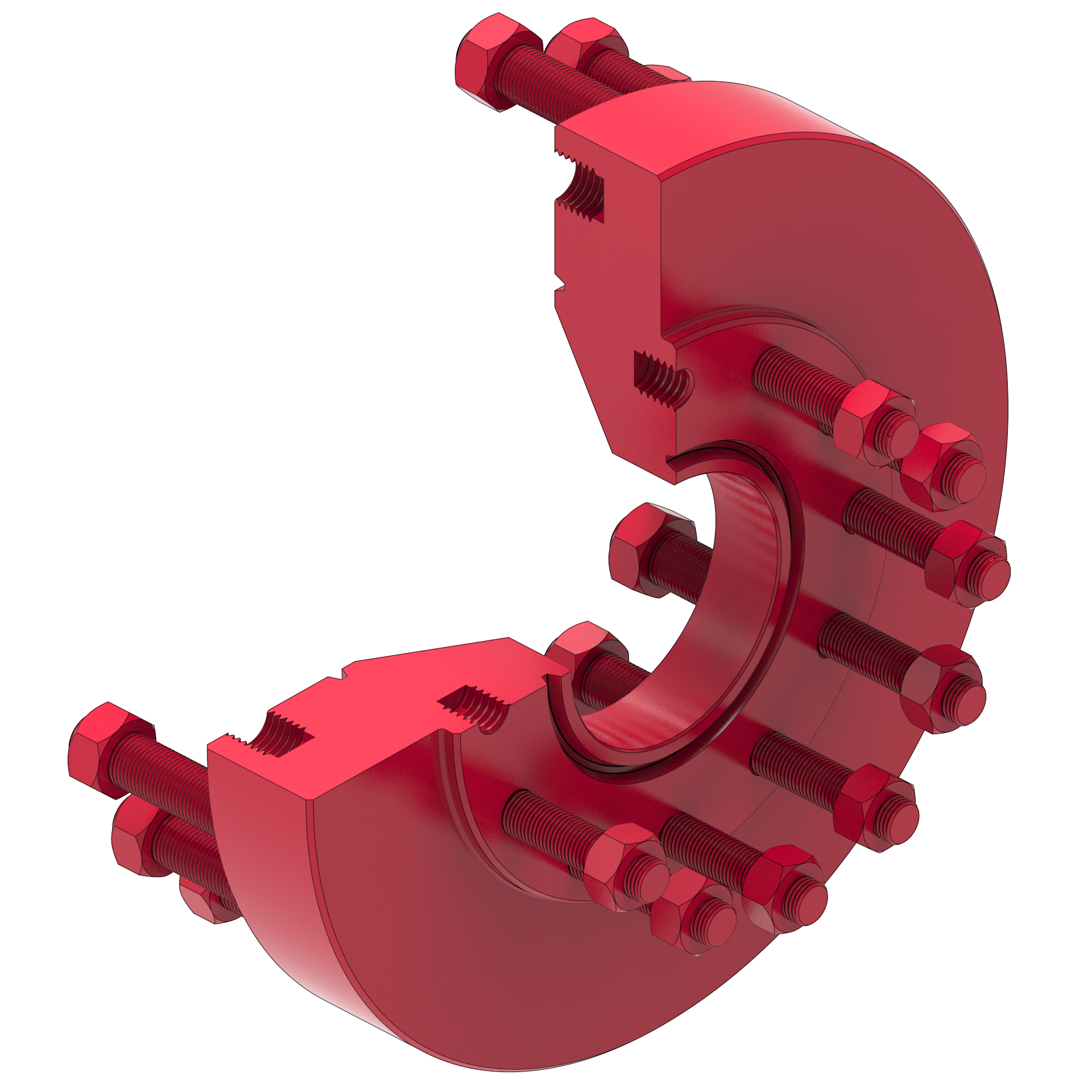

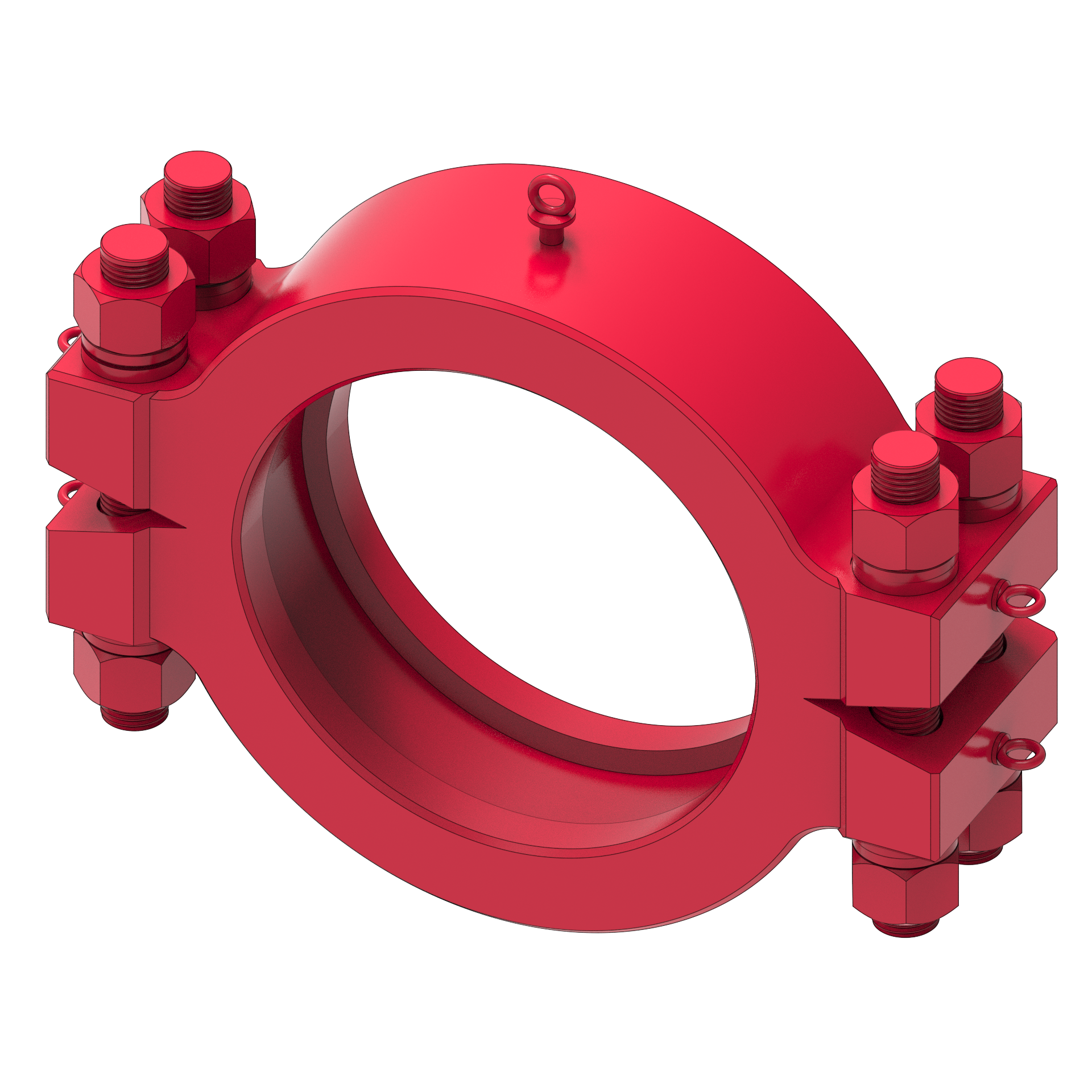

Hub Clamp End Connectors

We design, manufacture, and monogram API 16A clamps & hubs.

OILFIELD EQUIPMENT