d4f37c3a31021a6c30163c928b1ee8fa

d4f37c3a31021a6c30163c928b1ee8fa

Hydro, Inc., the largest independent pump rebuilder in the world, announces Hydro University.

With over 50 years of experience repairing, rebuilding, and optimizing pumps from all OEMs, Hydro’s team is uniquely qualified to teach and engage the next generation of industrial pump users. Hydro University is a focused resource for providing hands-on, industrial knowledge and applicable pump knowledge to optimize industrial operations and reduce maintenance costs.

“Hydro University is a truly unique offering,” says George Harris, owner and founder of Hydro, Inc. “Hydro has always been a leader in pump repair and pump health. We’re in a digital world now, and e-learning is aligned to 21st-century business. Hydro University lets us use new technologies to share practical knowledge on pump design, efficiency, and reliability. Digital learning through Hydro University is convenient, flexible, interactive, and serves many different learning styles,” Harris adds.

Mike Mancini, Hydro President of Total Solutions and Hydro University trainer, believes that the enhanced graphics make a significant difference in pump learning. “Hydro University uses 3D modeling for pumps in our training. We take you directly inside a pump and show you each element and how its performance affects efficiency, optimization, and energy savings,” Mancini shares. “Knowledge and experience in these areas help you improve your pump performance and reduce maintenance costs,” Mancini shares.

“Pumps are complex equipment, and the proper care of a pump will keep your line running and can even optimize energy efficiency for your overall operation,” states Bob Jennings, Hydro University Trainer and Hydro, Inc. Manager of Energy Upgrades. “At Hydro University, we are teaching about best efficiency points, vibration analysis, affinity laws’ use for system changes, and pump design configurations,” Jennings states.

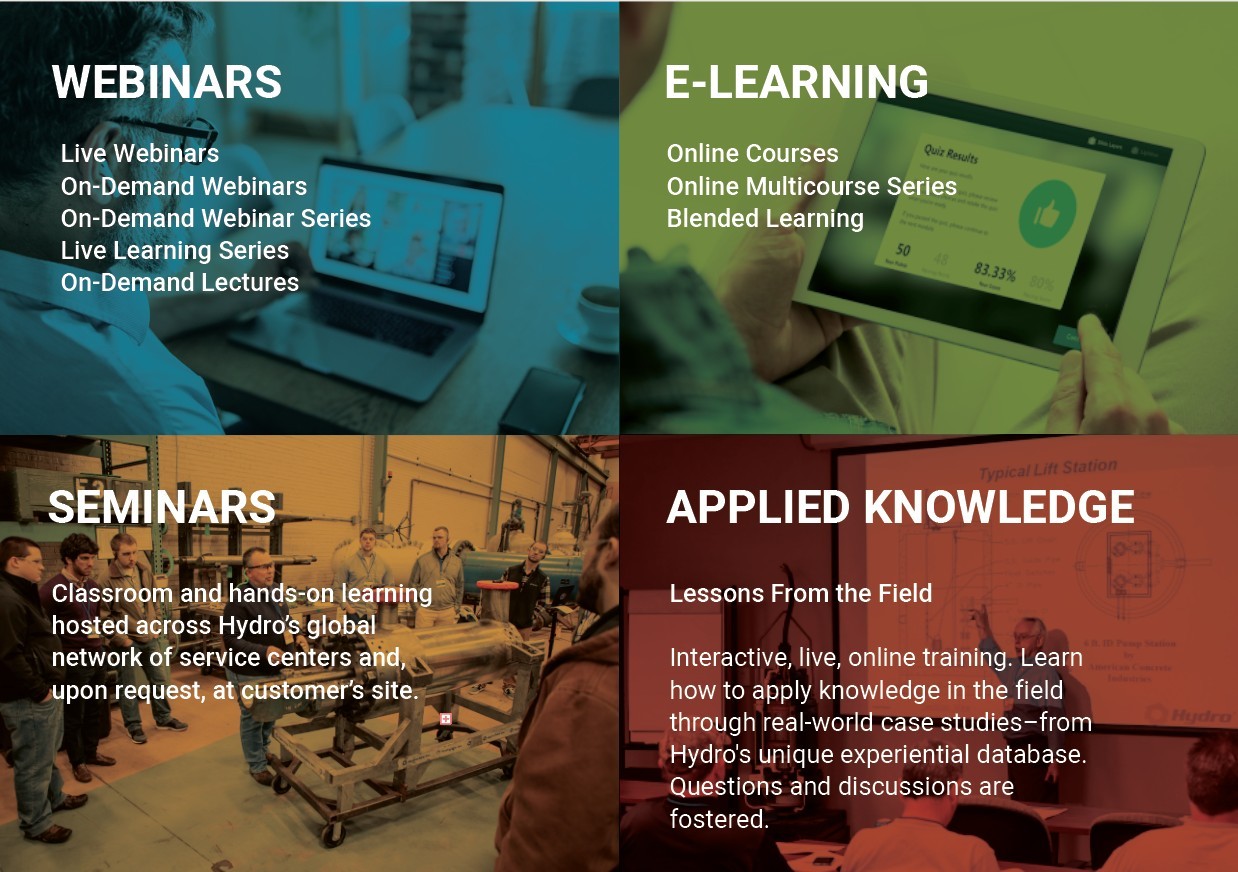

Hydro University will offer webinars, e-learning courses, seminars, and applied knowledge. On-line classes are available both live and on-demand. Training programs are designed for individuals seeking to expand their knowledge or skills and for companies looking to educate/train groups of employees. Some classes offer certificates for Personal Development Hours and Continuing Education credits. When safe to do so again, Hydro University will offer in-person training programs.

Pump Fundamentals (for Technicians and for Engineers), Introduction to Shaft Alignment, Generic Failure Modes, Inspection Guidelines, and Vibration Fundamentals are a few of the e-learning courses available today. Available webinar topics include NPSH, Pump Curves/Operate at BEP, Basic Pump Design, Introduction to Vibration Concepts, and Pump Testing. Hydro University program offerings are quickly expanding, including the availability of programs tailored to specific customer needs.

For more information visit hydromiddleeast.hydroinc.com/hydro-university or contact Hydro University here.

A large American energy company wanted a new data collection system to be integrated into its site historian along with process trending software to better diagnose system-related issues that can lead to maintenance issues.

Thanks to the help of an aftermarket service company, the energy company combined multiple sources of data and can now view complex mechanical vibration phenomena in parallel with plant process data. By comparing the two sets of data side by side, plant personnel will correlate process conditions with mechanical vibration data.

The service provider’s history of pump and rotating equipment knowledge helped to provide actionable analysis of pumps and other rotating equipment health—and a mechanism to provide additional engineering solutions to complex problems. Combined with the energy company’s focus on reliability and a history of maintaining their equipment, this system provided an improved method of data collection and analysis.

Source: https://www.pumpsandsystems.com/wireless-sensor-data-integration-existing-plant-historian

Hydro, Inc. is proud to announce our newest training platform, Hydro University. At Hydro University, our mission is to ensure pump users around the world have access to critical knowledge, troubleshooting methodology, technical skills, and strategies required to optimize industrial operations and reduce maintenance costs.

We strive to teach and engage our students to be the next generation of industrial pump users and provide the tools to assist them in achieving greater success in their careers, businesses, and industries.

With over 50 years of experience in the pump industry, Hydro offers a wide range of technical webinars, e-learning, and in-person seminars for end-users who want to learn more about pumping technology and build their skills within the field.

The topics are expansive and cover a breadth of knowledge such as centrifugal pump fundamentals, system optimization, vibration, failure modes, and much more. As an independent company, our flexibility also allows us to customize topics and programs to fit your individual needs.

Do you want to learn more about the intricacies of your pumps, how to effectively troubleshoot problems, or optimize pump operation?

Contact HydroUniversity@hydroinc.com today to learn more.

The pump shaft is the central component of the rotating element and is responsible for transmitting energy to the rotating components. The shaft carries the impellers, sleeves and couplings for the rotating element assembly. The stiffness of the combined assembly is responsible for ensuring that the pump stationary components do not come into contact with the rotating components.

Unfortunately, this is not always achieved and many pump rotors cannot be described as classically stiff. This can have dire consequences for machine reliability, particularly if, during the rotor build process, the technicians are not aware of the subtleties of the machine design.

Source: https://www.pumpsandsystems.com/hidden-dangers-shaft-stiffness