A large American energy company wanted a new data collection system to be integrated into its site historian along with process trending software to better diagnose system-related issues that can lead to maintenance issues.

Thanks to the help of an aftermarket service company, the energy company combined multiple sources of data and can now view complex mechanical vibration phenomena in parallel with plant process data. By comparing the two sets of data side by side, plant personnel will correlate process conditions with mechanical vibration data.

The service provider’s history of pump and rotating equipment knowledge helped to provide actionable analysis of pumps and other rotating equipment health—and a mechanism to provide additional engineering solutions to complex problems. Combined with the energy company’s focus on reliability and a history of maintaining their equipment, this system provided an improved method of data collection and analysis.

Source: https://www.pumpsandsystems.com/wireless-sensor-data-integration-existing-plant-historian

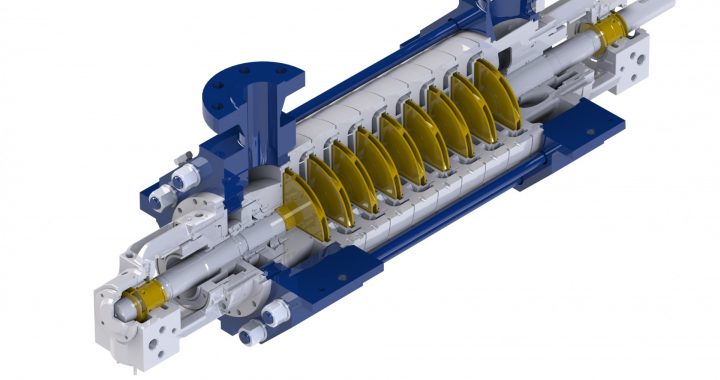

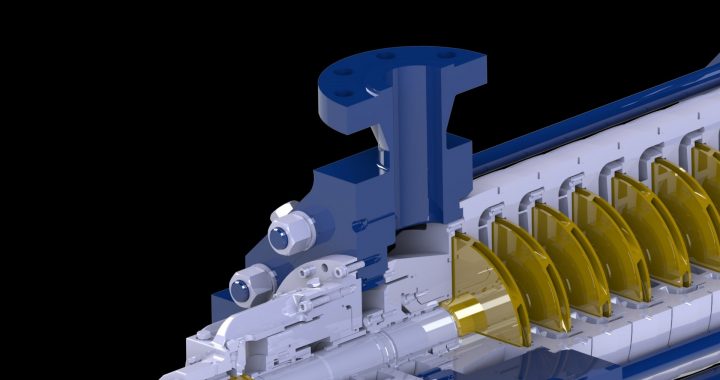

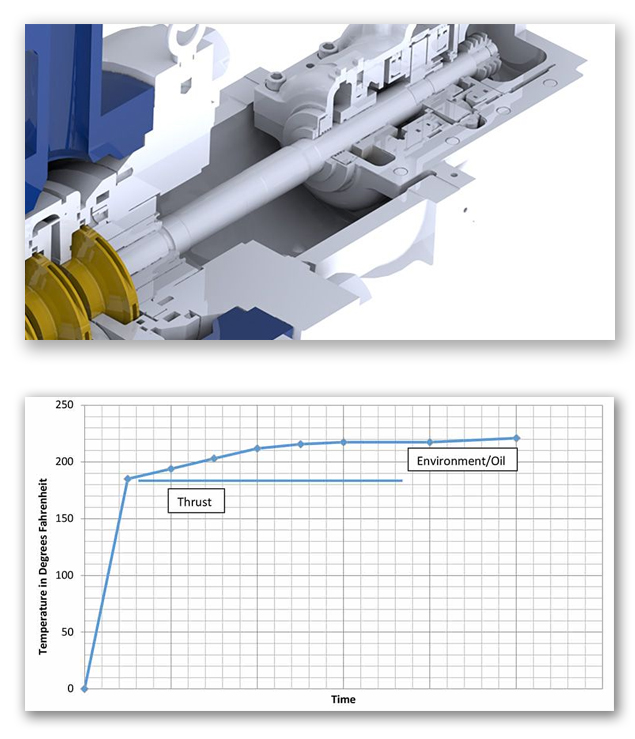

During the commissioning and startup of an alumina processing plant in the Middle East, a significant recurring pump issue was causing delays to the commissioning of the facility. When de-energizing the equipment, the live steam condensate vertical can pumps experienced repeated failures of all installed units. These seizures occurred at both the design fluid temperature and when pumping cold water.

During the commissioning and startup of an alumina processing plant in the Middle East, a significant recurring pump issue was causing delays to the commissioning of the facility. When de-energizing the equipment, the live steam condensate vertical can pumps experienced repeated failures of all installed units. These seizures occurred at both the design fluid temperature and when pumping cold water.